Technical Q&A and demo video

Artificial Intelligence! Speed & Safety need only Modeling!

NCB Inc. started business S/W development and processing company in 1997. NCBrain, our main product, was released in 2003 and has been

supplied to more than 1,700 customers with 7,000 seats, including Samsung, LG, Hyundai, KIA, Toyota, Honda and Mahindra. NCBrain has

been used as their standard fast and safe system for NC machining increase company profit by optimization and machining database. Thanks to all

these accumulated our technology & know-how, we’ve come to develop new concept of solution, called ‘AICAM’ which is artificial intelligence of

milling technique, and release it 2017. We, NCB Inc., will never stop contributing to our customers with the continuous development and practical

on-site technology.

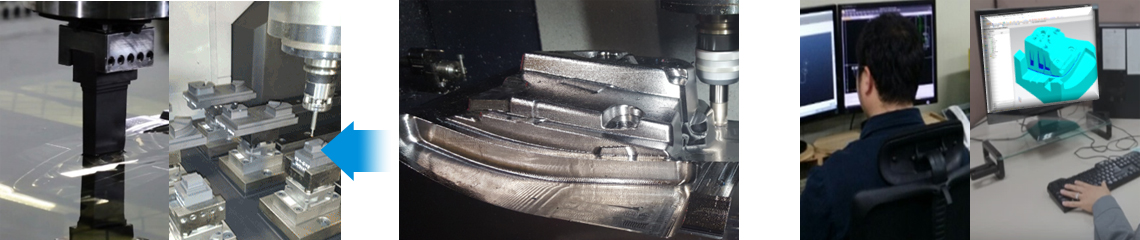

Automated operation! cost saving for core cutting

24 hours a day, 365 days a year !

easy, safe and fast unmanned machining

1. Start NC machining after just 5 click of CAM works

2. No need to worry about selecting tools and setting

time through ATC machining with 15 exclusive tools.

3. Increase lifespan and decrease machining time with

exclusive shrink fit holder and corner-R tool.

4. Best ideal database for NC machining by various tools

specification

5. Automatic Feedrate & RPM control by cutting load

calculation

6. Automatic toolpath addition for excessive load to cut

7. Automatic aircut delete for empty & little load to cut

8. Show the area of EDM or Over/ Less cutting

Current status of CAM&NC machining

Know-how involved for NC machining such as shape recognition, machining process, and tool choice etc.

Thus, a lot of cost & time needed because of excessive working time, technology gap, and human errors etc.

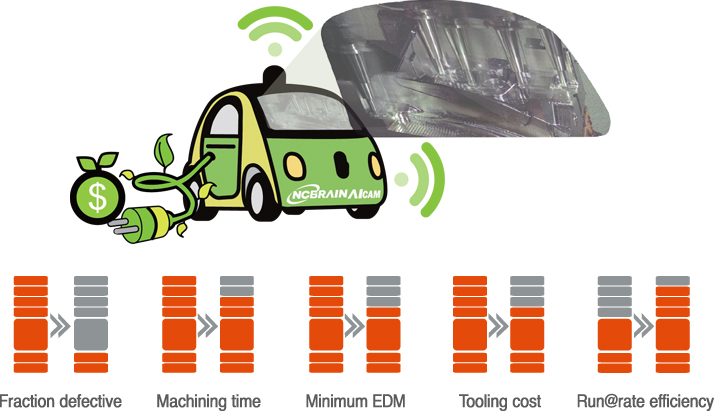

After NCBrain AICAM application

AICAM, self-driving concept of artificial intelligence, needs only modeling and leads to safe, fast, and unmanned automotive machining.

5 icon-clicking makes it possible not only to do unmanned machining & to reduce machining time but also to increase

Run@rate & to minimize

electrode & to cut down on tools cost.

Annual profit with 3 NC machines using AICAM

Standard : Middle level clients of mold & die industry in Korea (applicable to the machine over $130,000 only )

(Unit $)

(Unit $) | Effect of hiring CAM

engineers

(1~2 persons) | Reduce Machining time

Minimize EDM | Increase Run@rate | Cut down

on tooling cost |

| Expense | Annual salary +

management costs

60,000 | 1 NC / year : 120,000

3 NC / year : 360,000 | 1 NC / year : 120,000

3 NC / year : 360,000 | 1 NC / year : 12,000

3 NC / year : 36,000 |

Additional

profit | 60,000 / year | 360,000 * 20%

72,000 / year | 360,000 * 20%

72,000 / year | 36,000 * 30%

10,800 / year |

| Annual total additional profit 214,800 + equalizing quality |

NCBrain AICAM = Effect of hiring a great engineer

Know-how involved for NC machining such as shape recognition, machining process, and tool choice etc.

Thus, a lot of cost & time needed because of excessive working time, technology gap, and human errors etc.

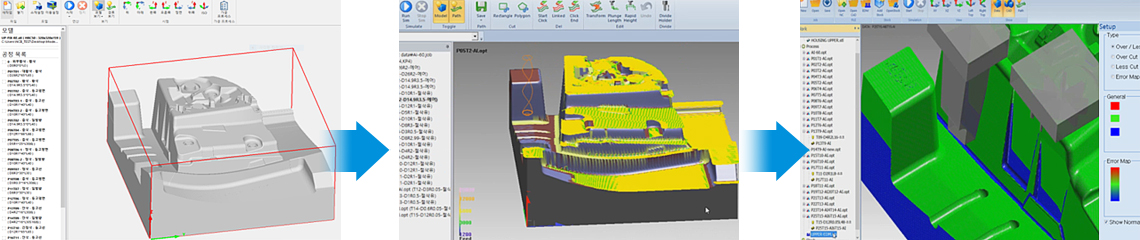

Use process

1st step, Create tool pattern by AICAM automatically.

2nd step, NC machinging followed by simulation and optimization edit.

3rd step, AUTO-DIFF verification, electrode check, and EDM simulation followed.

Automatic toolpath creation

Optimization

Verification

Machining of fifteen

tool automation

Verify electrode

model simulation

EDM operation

NCBrain AICAM Product component

1 single package composed of 3 S/W below and tools.

This package makes it possible to do unmanned automotive machining.

1. NCBrain CAM

toolpath creation

2. NCBrain Simulation

optimization

4. Exclusive shrink fit holder

6 Types(15EA) & CRN coating

5. Exclusive E/M

11 Types(55EA)

6. Exclusive cutter/TIP

1 Bull-nose/TIP(10EA)

(Unit $)

(Unit $)