Top-notch standard solution for NC milling by optimized database

To survive in mold industry?

Fast delivery & good quality / deficit by time & quality

▲ Cost = 100.000$, Delivery = 7days, Quality = A NCBrain User ▲ Cost = 150.000$ , Delivery = 10days , Quality = B Normal company

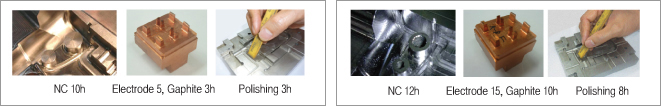

Mold delivery and quality are affected by how fast and good in NC milling.

NC milling totally depends on CAM data and engineer’s skill and experiences.

This causes big difference in quality and time, and there is big limit in CAM functions.

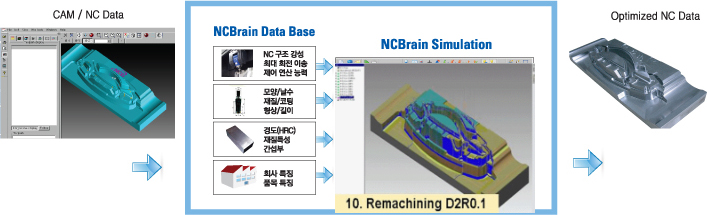

System with Data Base

Set up data base based on material, tool, equipment, and company trait.

NCBrain builds the best data base considering cutting condition of machine specification, tools, stocks, and items. Existing data base will be regenerate

into optimized NC data by simulation of NC Data. The optimized NC Data make the safest and the fastest machining at all times without any accident

considering feedrate control, tool path addition on overload area, and automatic aircut delete.

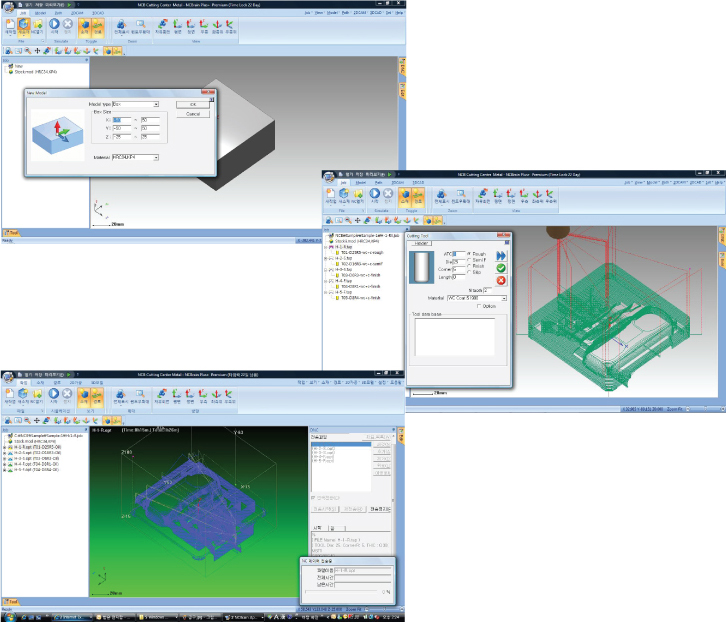

NCBrain main functions

Main functions by best Data Base automatically

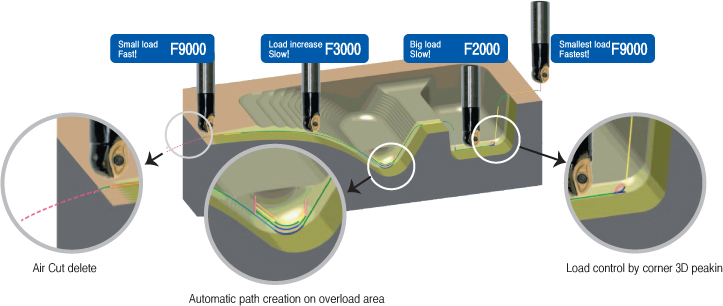

Feedrate control, toolpath creation, air cut delete

After 1 simple Simulation, more than 30 functions are realized such as feed rate control, time reduction, automatic tool path addition on overload area,

prevention of tool breakage etc. This makes it possible to do fast and safe NC milling even at night without stopping by ATC.

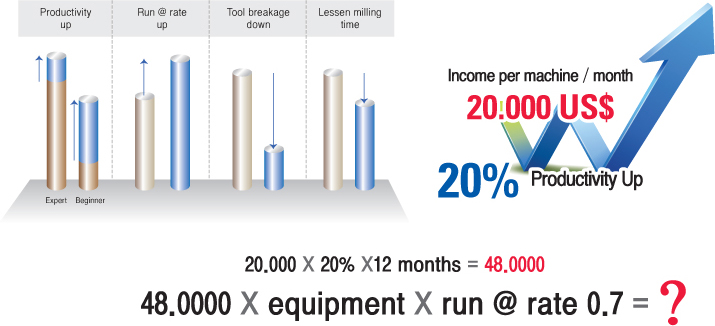

Effectiveness of NCBrain & Faculty of NCBrain

Effectiveness of NCBrain

- Reduction of milling time by optimized terms & upward Run@rate by continuous ATC use

- Prevention of tool breakage & easy process control by optimized milling information

- Quick ROI & easy, immediate manipulation

Faculty of NCBrain

- Best ideal database for NC milling by various tools specification

- Automatic Feedrate & RPM control by automatic load calculation

- Automatic toolpath addition for excessive load to cut

- Automatic aircut delete for empty & little load to cut

- More than 30 functions autualized after 1 simple simulation

ROI

Profit rate by CNC numbers per year

customers & application

Appox.1700 clients 7000 COPY From Top Global company to small company, using our S/W

The best optimized system used in electronics, car, mobile variety product of press, mold, die-casting and blow-mold by

NC machining part with data base.