| 2015 | SMART-UAX version 2 released |

| 2013 | SMART-UAX commercialized |

| 2012 | Concept machine released at expo |

| 2011 | Co-patent applied by Hwacheon & NCB |

| 2010 | SMART Machine development start |

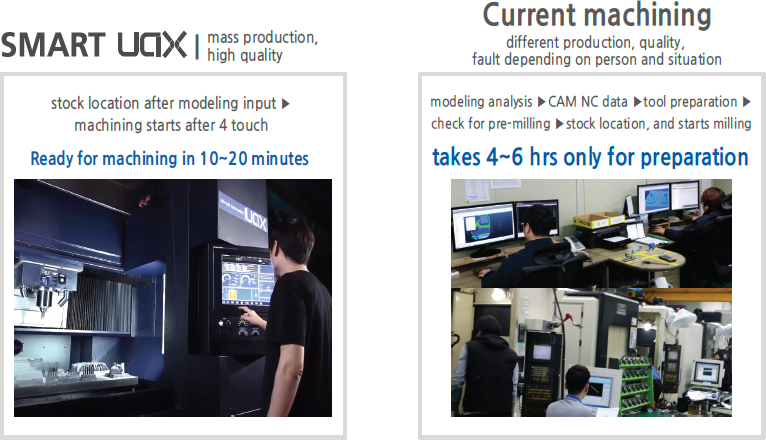

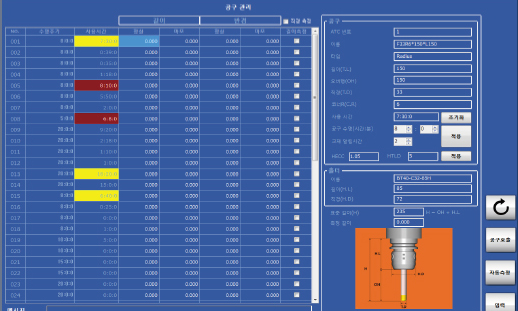

| SMART-UAX | Current machining | |

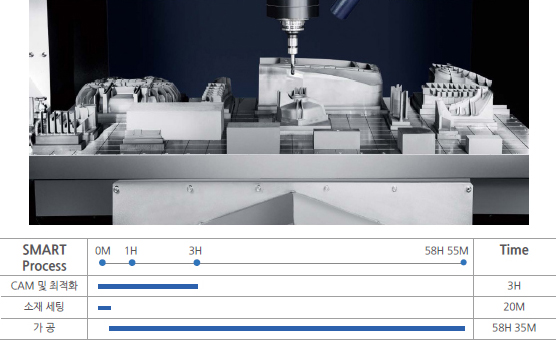

| 1. Ready for machining | - Put stock after modeling - Beginning with 4 Touch only - Ready for machining in 10~20 minutes | - Modeling analysis - Prepare CAM & NC DATA - Set for tools - Modify every status before machining - Beginning with put stock - Ready for machining in 4~6 hours |

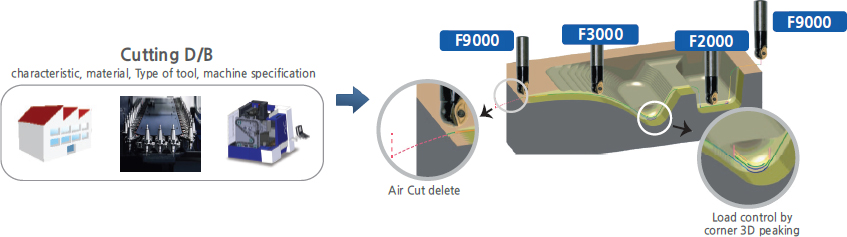

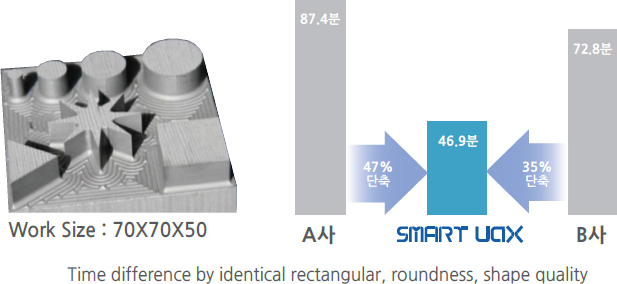

| 2. Time | - Otimized machining with best D/B! - 30~50% faster with optimized adjustable feedrate | - Wide variations depending on technical level! - Limit with machine speed |

| 3. Quality | - High quality with equivalence - No defect | - Wide variations depending on technical level! - Inevitable human error |

| 4. Tool span | - Save expense with automatic process - Automatic sensor for breakage | - Manual check & usage increased - Human error & quality decreased |

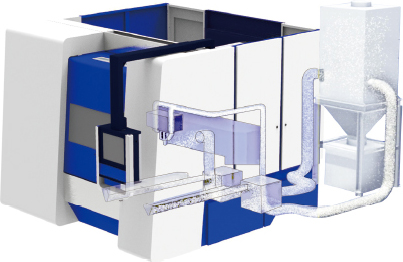

| 5. Machine span | - Best dust collector system - Automatic collision prevention - Guarantee long-term accuracy & span | - Wide variations depending on machine - No collision check - Span depending on maintenance |

| 6. Machine management | - Automatic system - Effcient operation & save electric charge | - Manual check - Waste of time & excessive electric charge |

| 7. Unmanned machining | - Big table & mass production - Possible during more than 48 hrs | - Limit with table size - Wide variations with technical level |

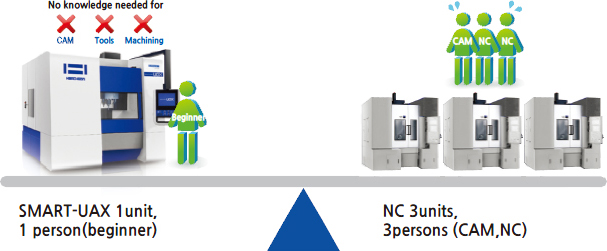

| 8. Output | - Constant 365-day production - Possible for more than old 3 machine or new 2 machine | - Depending on person & situation |

| 9. ROI | - SMART-UAX 1 unit, including S/W, technique, tools etc | - M/C, CAM, tool holder, S/W engineer,... constant maintenance expense etc |

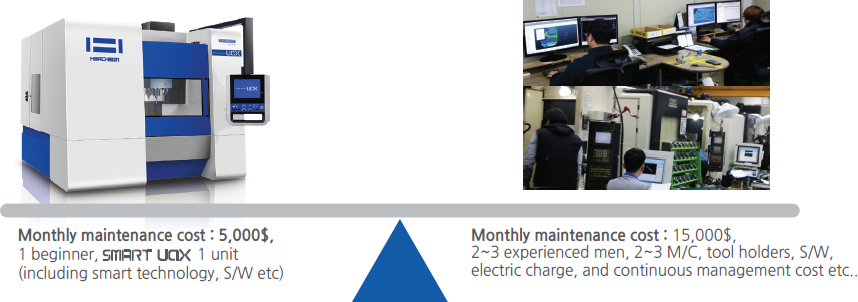

| SMART-UAX | Current NC machining | |

| Identical investment terms | 1 unit( including Smart technology S/W,tools) | NC machine 2~3 units, tools, CAM etc |

| yearly maintenance cost | 1 beginner, tool, electric charge 60,000US$ | CAM, 2~3 experienced men, tool &electric charge 2 times, AMC etc 180,000US$ |

| production | short-term production : current 2~3 units better long-term production : faster SMART UAX better without stop | |